Inqubo Yokukhiqiza IMargarine

Inqubo Yokukhiqiza IMargarine

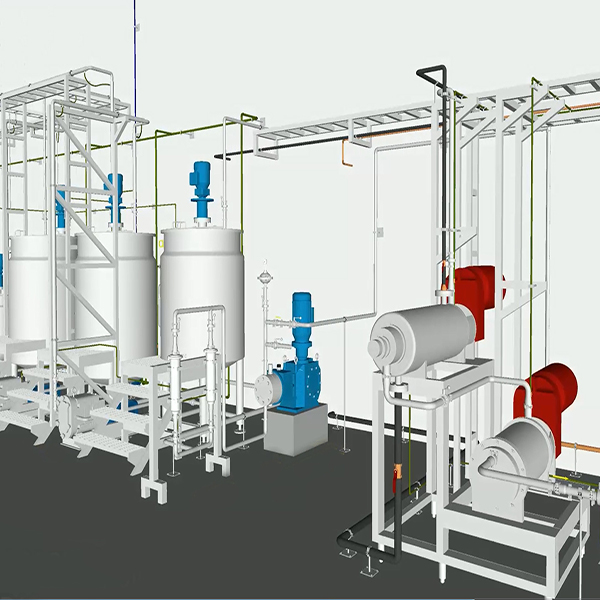

Ukukhiqizwa kwemajarini kuhlanganisa izingxenye ezimbili: ukulungiswa kwempahla eluhlaza kanye nokupholisa kanye nokwenza ipulasitiki. Imishini eyinhloko ihlanganisa amathangi okulungiselela, iphampu ye-HP, i-votator (i-scraped surface heat exchanger), umshini we-pin rotor, iyunithi yesiqandisi, umshini wokugcwalisa imajarini nokunye.

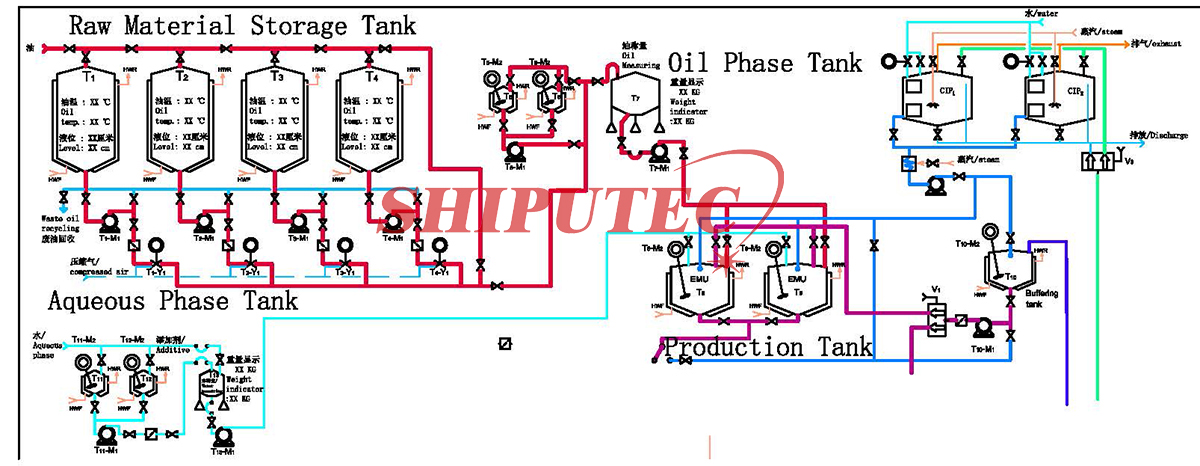

Inqubo yangaphambili iyingxube yesigaba samafutha kanye nesigaba samanzi, ukukalwa kanye nengxube ye-emulsification yesigaba samafutha kanye nesigaba samanzi, ukuze kulungiselelwe ukuphakelwa kwezinto ezibonakalayo zenqubo yakamuva. Inqubo yokugcina ukupholisa ukupholisa ipulasitiki nokupakishwa komkhiqizo.

Inqubo yokulungisa izinto ezingavuthiwe zemajarini ikhonjisiwe kuMfanekiso 1:

- 1.Ubisi olubilile

Abanye imajarini ifomula ukwengeza ubisi, futhi ubisi emva lactic acid amagciwane ukuvutshelwa kungaveza ukunambitheka efanayo ukhilimu wemvelo, ngakho imboni ubisi olubilile namanzi exutshwe.

- 2.Ukuxuba amanzi

Izithasiselo ezincibilikayo emanzini namanzi kufomula yemajarini, njengobisi oluvutshiwe, usawoti, izilondolozi, njll., zengezwa ekuxubeni kwesigaba samanzi kanye nethangi lemitha ngesilinganiso esinqunyiwe sokuxubha nokuxuba, ukuze isigaba samanzi izingxenye zincibilika zibe isisombululo esifanayo.

- 3.Ukuxuba isigaba samafutha

Uwoyela ongahluziwe wokucaciswa okuhlukile uxutshwa kuqala ethangini lokuxuba uwoyela ngokwesilinganiso esinqunyiwe, bese kufakwa izithasiselo ezincibilika uwoyela, njenge-emulsifier, i-antioxidant, i-pigment encibilikayo kawoyela, i-cellulose encibilika uwoyela, njll., isigaba samafutha ngokwesilinganiso, esixutshwe nethangi lemitha, futhi sinyakaziswa ukuze kwakhiwe isigaba samafutha esifanayo.

- 4.I-emulsion

Inhloso ye-emulsification ye-margarine ukwenza isigaba samanzi ngokulinganayo futhi sihlakazeke ngokuzinzile esigabeni samafutha, futhi izinga lokuhlakazeka lesigaba se-aqueous linomthelela omkhulu kwikhwalithi yomkhiqizo. Ngenxa yokuthi ukunambitheka kwemajarini kuhlobene eduze nobukhulu bezinhlayiya zesigaba samanzi, ukusakazwa kwama-microorganisms kwenziwa esigabeni samanzi, ubukhulu bamagciwane ajwayelekile buyi-1-5 microns, ngakho-ke amaconsi amanzi ku-10-20. ama-microns noma ububanzi obuncane bungakhawulela ukusakazeka kwamagciwane, ngakho-ke ukuhlakazeka kwesigaba samanzi kuhle kakhulu, izinhlayiya zesigaba samanzi zincane kakhulu zizokwenza imajarini ilahlekelwe ukunambitheka; Ukusabalalisa akwanele, i-particle yesigaba samanzi inkulu kakhulu, izokwenza i-metamorphism ekhohlakele yemajarini. Ubudlelwano phakathi kwezinga lokuhlakazwa kwesigaba se-aqueous ku-majarini kanye nemvelo yomkhiqizo cishe bungokulandelayo:

| 水滴直径 Ubukhulu bokwehla kwamanzi (微米 micrometer) | 人造奶油性质 (Taste of Margarine) |

| ngaphansi kwe-1 (cishe ama-80-85% wesigaba samanzi) | Ukunambitheka okunzima nokuncane |

| 30-40 (ngaphansi kuka-1% wesigaba samanzi) | Ukunambitheka okuhle, kulula ukubola |

| 1-5 (cishe u-95% wesigaba samanzi) | Ukunambitheka okuhle, akulula ukubola |

| 5-10 (cishe u-4% wesigaba samanzi) | |

| I-10-20 (cishe i-1% yesigaba samanzi) |

Kungabonakala ukuthi ukusebenza kwe-emulsification kufanele kufinyelele izinga elithile lezidingo zokuhlakazeka.

Inhloso yokuxuba isigaba samanzi kanye nesigaba samafutha ngokwehlukana futhi ngokulinganayo nesigaba sangaphambili ukuqinisekisa ukuhambisana okufanayo kwe-emulsion yonke ngemva kwe-emulsification nokuxuba amafutha namanzi izigaba ezimbili. Ukuxuba kwe-Emulsification kungukuthi, inkinga yokusebenza yi-50-60 degrees, isigaba samanzi sengezwa esigabeni sikawoyela esilinganisiwe, ekunyakazeni komshini noma umjikelezo wepompo onyakazayo, yisigaba samanzi esihlakazwe ngokugcwele esigabeni samafutha, ukwakheka kwe-latex. Kodwa lolu hlobo uketshezi latex engazinzile kakhulu, yeka enyakazayo kungase kube phezu uwoyela inkundla yokudlala nokuhlukaniswa mkhuba amanzi.

Ngemuva kokulethwa kwe-emulsion ehlanganisiwe, inqubo yokupholisa kanye ne-plasticizing yenziwa kuze kube yilapho umkhiqizo uhlanganiswa.

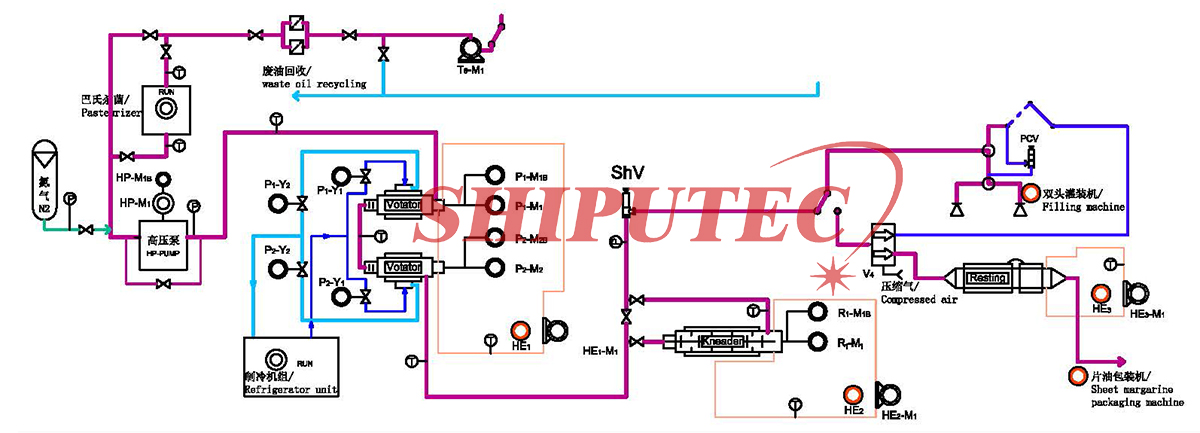

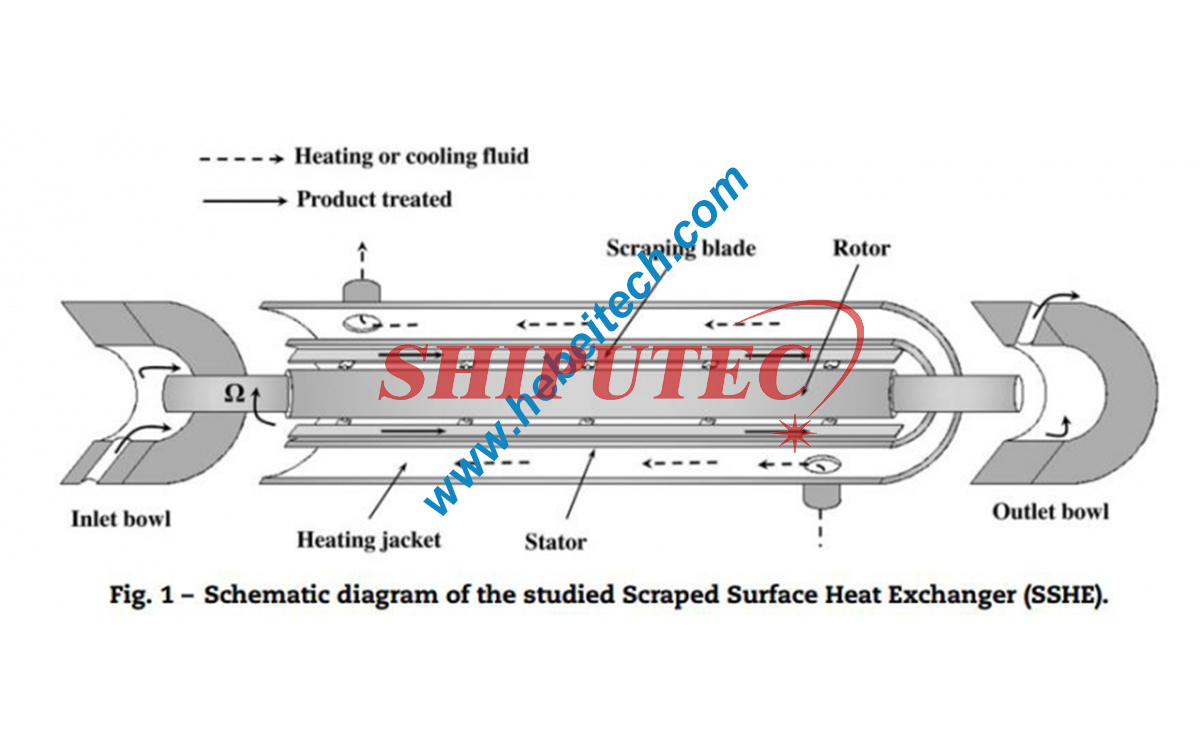

I-emulsion kufanele ipholiswe futhi yenziwe ngepulasitiki ukuze ikhiqize umkhiqizo we-margarine oguquguqukayo. Njengamanje, isebenzisa idivayisi eqhubekayo yokucisha ipulasitiki yokucisha, okuhlanganisa ivoti noma ebizwa nge-scraped surface heat exchanger (iyunithi A), umshini wephinikhodi noma umshini wokuxova (iyunithi C) kanye neshubhu lokuphumula (iyunithi B). Inqubo yezobuchwepheshe iboniswa kuMfanekiso 2:

Lolu hlelo lokusebenza lunezici ezilandelayo:

1. Ukusebenza okuqhubekayo okungangenisi umoya ngomfutho ophezulu

I-emulsion exutshwe ngaphambili ifakwa kusilinda sokucisha ngepompo yokucindezela okukhulu komvoti. Ukucindezela okuphezulu kunganqoba ukumelana kulo lonke iyunithi, ngaphezu kokusebenza kokucindezela okuphezulu kungenza umkhiqizo ube mncane futhi ubushelelezi. Ukusebenza okuvaliwe kungavimbela umoya nomoya ngenxa yokucisha kanye nokufingqa kwamanzi okuxutshwe ne-emulsion, kuqinisekise izidingo zezempilo zomkhiqizo, kunciphise ukulahlekelwa kwesiqandisi.

2. Ukucisha kanye ne-emulsification

I-emulsion icinywa nge-ammonia noma i-Freon ku-votator ukupholisa i-emulsion ngokushesha, ukuze ukukhiqizwa kwezinhlayiya ezincane ze-crystalline, ngokuvamile i-1-5 microns, ukuze ukunambitheka kube okubucayi. Ngaphezu kwalokho, i-scraper ku-shaft ejikelezayo ku-votator ixhunywe eduze nodonga lwangaphakathi lwesilinda, ngakho-ke i-scraper esebenzayo ayikwazi nje ukuklabha ngokuqhubekayo i-crystallization enamathela odongeni lwangaphakathi, kodwa futhi yenza i-emulsion ihlakazeke ukuze ihlangabezane ne-scraper. izidingo ze-emulsification yethoni.

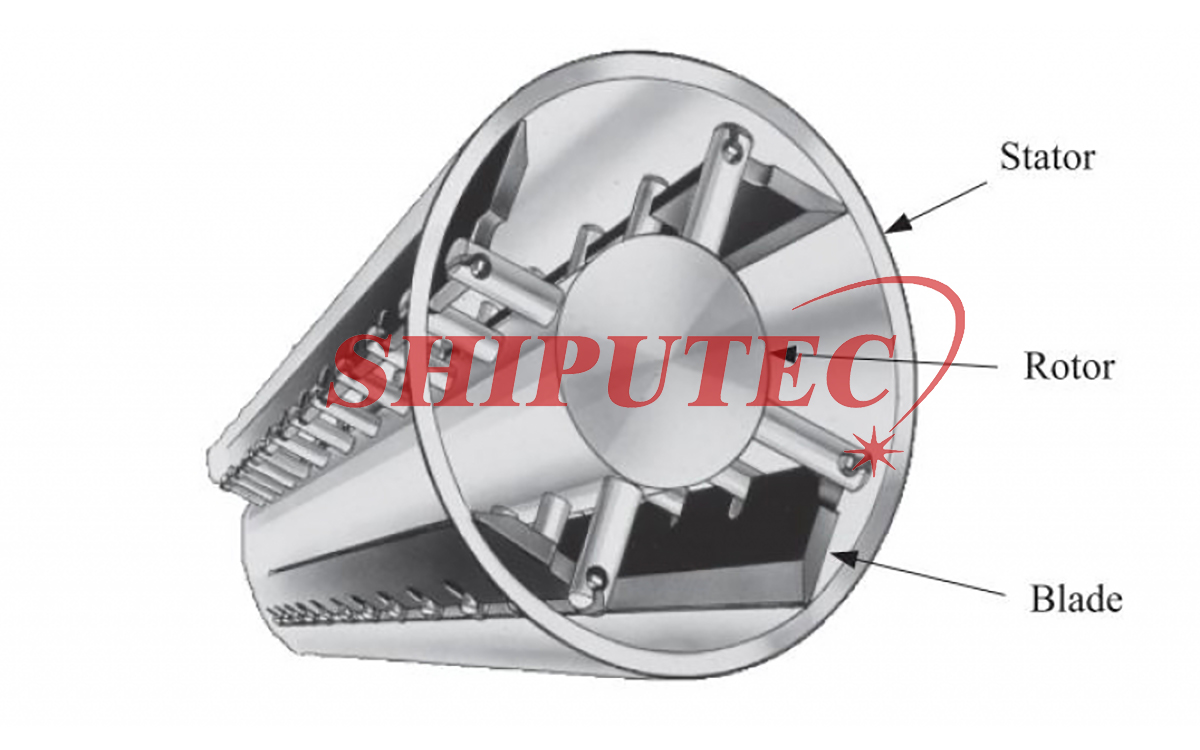

3. Ukuxova nokususa ukuqina (umshini we-pin rotor)

Nakuba i-emulsion epholiswe yi-votator isiqalile ukukhiqiza i-crystallization, isadinga ukukhula ngokuhamba kwesikhathi. Uma i-emulsion ivunyelwe ukuba icwebezele ekuphumuleni, kuzokwakhiwa inethiwekhi yamakristalu e-lipid aqinile. Umphumela wukuthi i-emulsion epholile izokwakha inqwaba enzima kakhulu ngaphandle kwepulasitiki. Ngakho-ke, ukuze uthole imikhiqizo ye-margarine nge-plasticity ethile, isakhiwo senethiwekhi kufanele siphulwe ngezindlela zemishini ngaphambi kokuba i-emulsion idale isakhiwo senethiwekhi jikelele, ukuze kuzuzwe umphumela wokunciphisa ukuqina. Ukuxova kanye nokunciphisa ukuqina kwenziwa ikakhulukazi emshinini we-pin rotor.

Iyunithi A (umvoti) iyithuluzi lokupholisa le-scraper. I-emulsion ishayelwa kuyunithi evaliwe A (i-votator) ngepompo yokucindezela okuphezulu. Impahla idlula esiteshini phakathi kwesilinda sokupholisa kanye ne-shaft ejikelezayo, futhi izinga lokushisa lempahla lehla ngokushesha ngokucinywa kwendawo yokupholisa. Imigqa emibili ye-scrapers ihlelwe ebusweni be-shaft. Amakristalu akhiwe endaweni engaphakathi yomvoti asulwa isikrufu esizungezayo esinesivinini esikhulu ukuze ngaso sonke isikhathi siveze indawo epholile entsha futhi sigcine ukudluliswa kokushisa okuphumelelayo. I-emulsion ingahlakazwa ngaphansi kwesenzo se-scraper. Lapho impahla idlula iyunithi A (i-votator), izinga lokushisa lehla libe ngama-degree angu-10-20, eliphansi kunephuzu lokuncibilika lamafutha. Nakuba amafutha eqala ukucwebezela, awakakabi isimo esiqinile. Ngalesi sikhathi, i-emulsion isesimweni sokupholisa futhi iwuketshezi oluwugqinsi.

I-axis yokuzungezisa yeyunithi A (umvoti) ayinalutho. Ngesikhathi sokusebenza, amanzi ashisayo angama-50-60 degrees athululelwa phakathi nendawo ye-axis yokujikeleza ukuvimbela i-crystallization eboshiwe futhi iphulukiswe ku-axis futhi ibangele ukuvinjelwa.

Iyunithi C (umshini we-pin rotor) iyithuluzi lokuxova nokususa ukuqina, njengoba kukhonjisiwe emfanekisweni ongenhla. Imigqa emibili yezinsimbi zensimbi ifakwe ku-shaft ejikelezayo, futhi umugqa wensimbi engaguquki ufakwe odongeni lwangaphakathi lwesilinda, olunyakaziswa ngamabhothi ensimbi ku-shaft futhi angathinti. Lapho i-shaft ijikeleza ngesivinini esikhulu, ama-bolts ensimbi ku-shaft adlula igebe lama-bolts ensimbi engaguquki, futhi impahla ihlanganiswe ngokugcwele. Ngaphansi kwalesi senzo, ingakhuthaza ukukhula kwamakristalu, ibhubhise isakhiwo senethiwekhi yekristalu, yakha amakristalu angapheli, inciphise ukuhambisana, futhi yandise ipulasitiki.

Iyunithi C (umshini we-pin rotor) idlala kuphela umthelela oqinile wokuxova ngobusuku obubanda kakhulu, ngakho idinga kuphela ukulondolozwa kokushisa futhi ayidingi ukupholisa. Njengoba ukushisa kwecrystallization kukhishwa (cishe 50KCAL/KG), kanye nokushisa okukhiqizwa ukungqubuzana kokuxova, izinga lokushisa lokukhipha iyunithi C (i-pin rotor macjhine) liphakeme kunalelo lokushisa okuphakelayo. Ngalesi sikhathi, i-crystallization icishe ibe ngu-70% ephelele, kodwa isathambile. Umkhiqizo wokugcina ukhishwa nge-valve ye-extrusion, futhi izoba nzima ngemva kwesikhathi esithile.

Ngemuva kokuthi imajarini ithunyelwe kusuka kuyunithi ye-C (umshini we-pin rotor), idinga ukuphathwa ngokushisa ekushiseni okuthile. Ngokuvamile, umkhiqizo ubekwe endaweni yokushisa engu-10 degrees ngaphansi kwendawo yokuncibilika isikhathi esingaphezu kwamahora angu-48. Lokhu kwelashwa kubizwa ngokuthi ukuvuthwa. Umkhiqizo ophekiwe ungathunyelwa ngqo endaweni yokucubungula ukudla ukuze usetshenziswe.