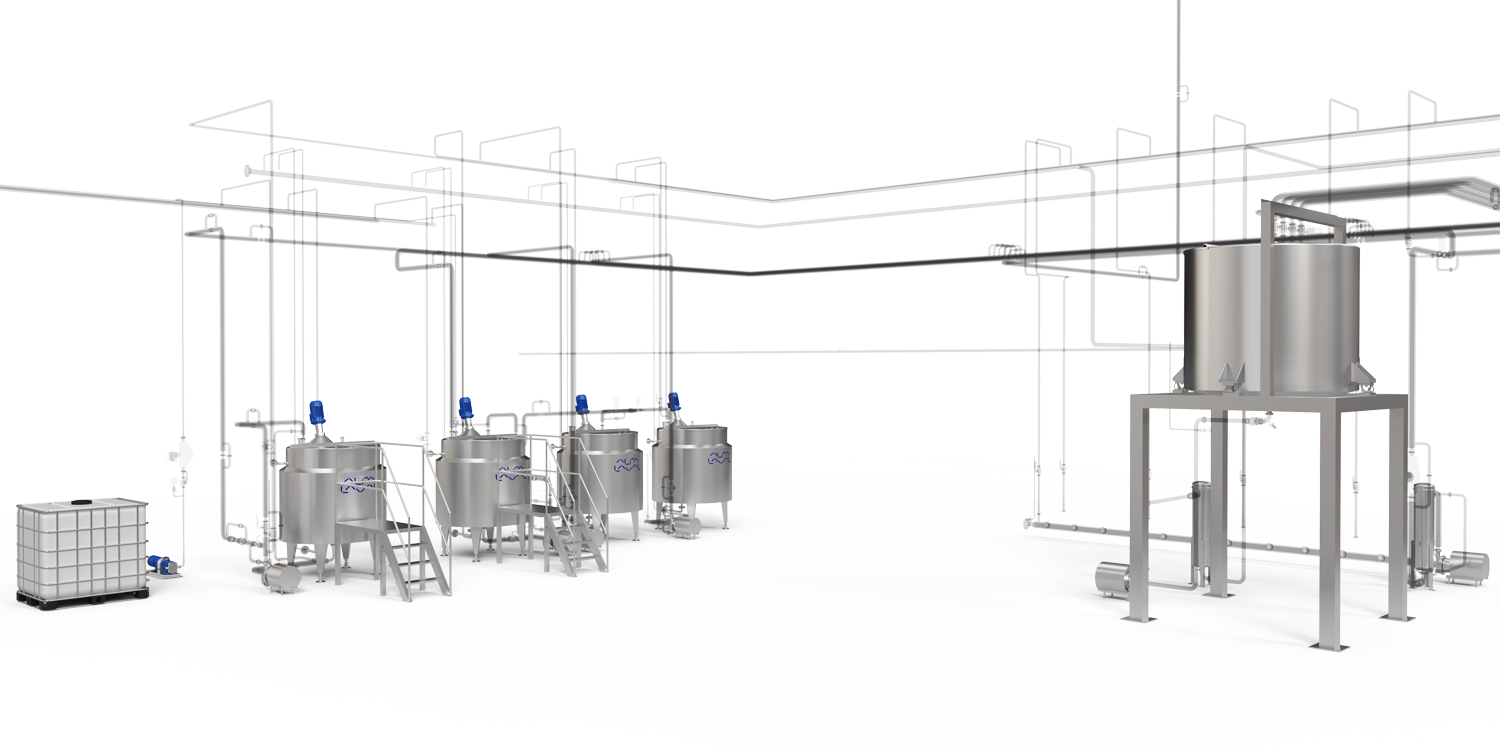

Inqubo yokukhiqiza imajarini inezigaba ezinhlanu: isigaba sikawoyela esinokulungiswa kwe-emulsifier, isigaba samanzi, ukulungiswa kwe-emulsion, i-pasteurization, i-crystallization kanye nokupakishwa. Noma yikuphi ukukhiqizwa okweqile kubuyiselwa ngeyunithi eqhubekayo yokusebenza kabusha ethangini le-emulsion.

Isigaba sikawoyela kanye nokulungiswa kwe-emulsifier ekukhiqizeni imajarini

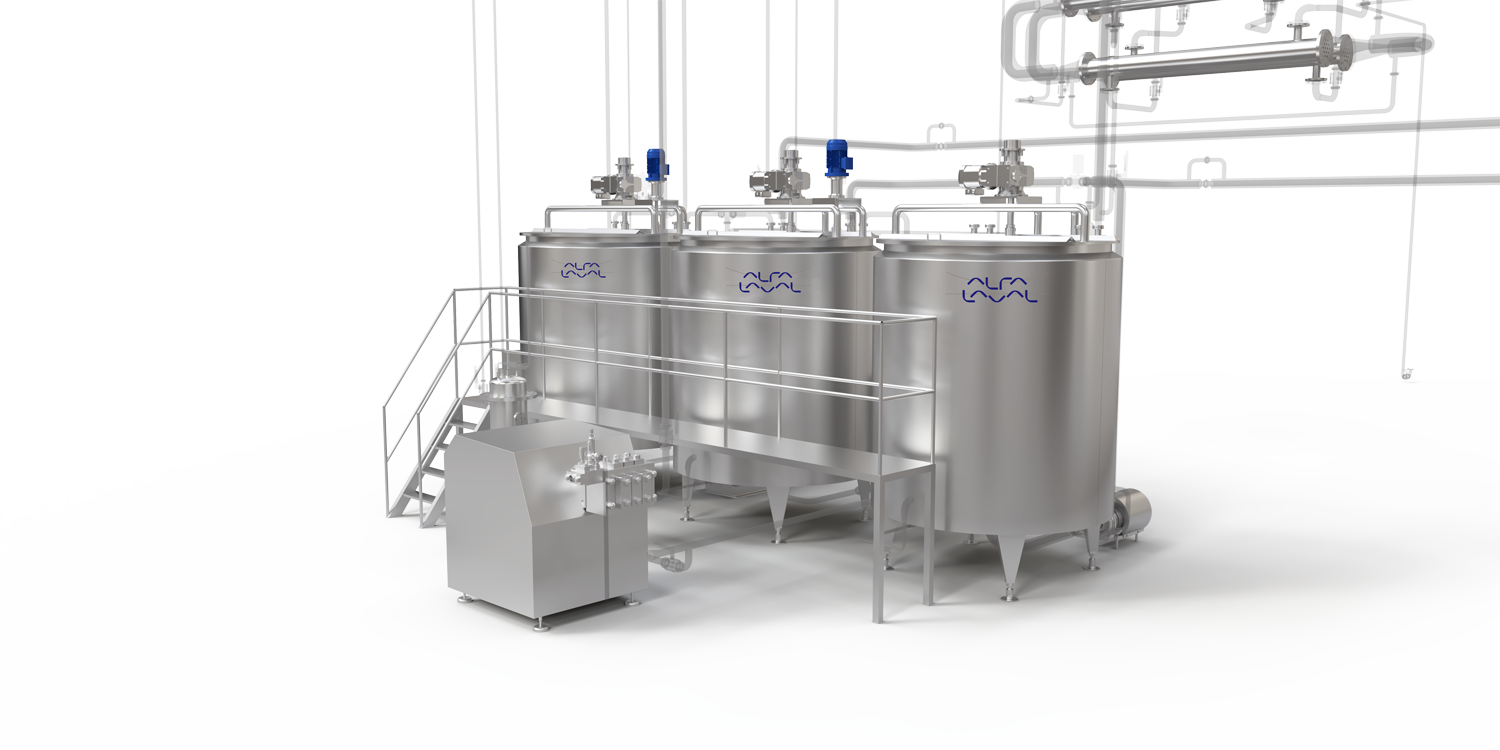

Iphampu idlulisa uwoyela, amafutha noma uwoyela ohlanganisiwe usuka emathangeni okugcina ngesihlungi uye ohlelweni lokukala isisindo. Ukuze uthole isisindo sikawoyela esifanele, leli tanki lifakwa ngaphezu kwamaseli omthwalo. Amafutha ahlanganisiwe axubene ngokusho kweresiphi.

Ukulungiswa kwe-Emulsifier kwenziwa ngokuxuba amafutha ne-emulsifier. Uma uwoyela usufinyelele izinga lokushisa elicishe libe ngu-70°C, izithasiselo ezifana ne-lecithin, i-monoglycerides ne-diglycerides, ngokuvamile eziyimpushana, zengezwa mathupha ethangini le-emulsifier. Ezinye izithako ezincibilika ngamafutha njengombala ne-flavour zingase zengezwe.

Isigaba samanzi ekukhiqizeni imajarini

Amathangi afakiwe ahlinzekwa ukukhiqizwa kwesigaba samanzi. I-flow meter idosela amanzi ethangini lapho eshiselwa khona ezingeni lokushisa elingaphezu kuka-45ºC. Izithako ezomile ezifana nosawoti, i-citric acid, ama-hydrocolloid noma impushana yobisi olukhihliziwe ingase yengezwe ethangini kusetshenziswa izinto ezikhethekile ezifana ne-powder funnel mixer.

Ukulungiswa kwe-emulsion ekukhiqizeni imajarini

I-emulsion ilungiswa ngokudosa amafutha namafutha ngenhlanganisela ye-emulsifier kanye nesigaba samanzi ngokulandelana okushiwo. Ukuxuba isigaba samafutha kanye nesigaba samanzi kwenzeka ethangini le-emulsion. Lapha, ezinye izithako, njenge-flavour, iphunga kanye nombala, zingangezwa ngesandla. Iphampu idlulisela i-emulsion ewumphumela ethangini lokuphakelayo.

Imishini ekhethekile, njenge-mixer ye-shear ephezulu, ingasetshenziswa kulesi sigaba senqubo yokwenza i-emulsion ibe yinhle kakhulu, ibe mincane futhi iqine, nokuqinisekisa ukuthintana okuhle phakathi kwesigaba samafutha kanye nesigaba samanzi. I-emulsion emihle ephumayo izodala imajarini yekhwalithi ephezulu ebonisa ipulasitiki enhle, ukuhambisana nesakhiwo.

Ipompo ibe isidlulisela phambili i-emulsion endaweni ye-pasteurization.

I-Crystallization ekukhiqizeni imajarini

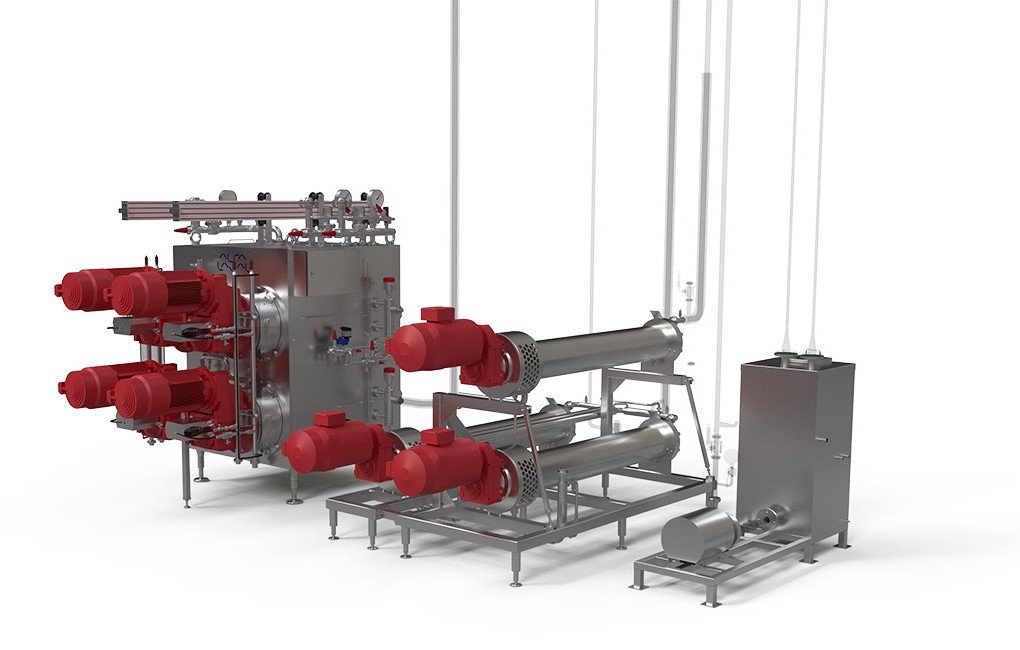

Iphampu yengcindezi ephezulu idlulisela i-emulsion ku-high-pressure scraped surface heat exchanger (SSHE), ehlelwa ngokuya ngesilinganiso sokugeleza kanye neresiphi. Kungase kube namashubhu okupholisa ahlukahlukene anosayizi abahlukene nezindawo zokupholisa ezihlukene. Isilinda ngasinye sinesistimu yokupholisa ezimele lapho isiqandisi (imvamisa i-ammonia R717 noma i-Freon) sijovwa khona ngokuqondile. Amapayipi omkhiqizo axhuma i-cylinder ngayinye komunye nomunye. Izinzwa lokushisa endaweni ngayinye ziqinisekisa ukupholisa okufanele. Isilinganiso sokucindezela esiphezulu singamabha ayi-120.

Kuye ngeresiphi kanye nesicelo, i-emulsion ingase idinge ukudlula iyunithi yesisebenzi esisodwa noma ngaphezulu ngaphambi kokupakisha. Amayunithi ezisebenzi zephinikhodi aqinisekisa ipulasitiki efanele, ukungaguquguquki nokwakheka komkhiqizo. Uma kudingeka, i-Alfa Laval inganikeza ithubhu yokuphumula; nokho, abahlinzeki bemishini yokupakisha abaningi banikeza eyodwa.

Iyunithi yokusebenza kabusha eqhubekayo

Iyunithi eqhubekayo yokuphinda isebenze iklanyelwe ukuphinda incibilike yonke imikhiqizo eyeqile edlula umshini wokupakisha ukuze ucutshungulwe kabusha. Ngesikhathi esifanayo, igcina umshini wokupakisha ungenayo i-backpressure engafuneki. Lolu hlelo oluphelele luqukethe isishintshi sokushisa sepuleti, iphampu yamanzi ejikelezayo epholile, nesifudumezi samanzi.

Isikhathi sokuthumela: Jun-21-2022