I-Scraped Surface Heat Exchangers-SP Series

Izici ezihlukile zochungechunge lwe-SP SSHEs

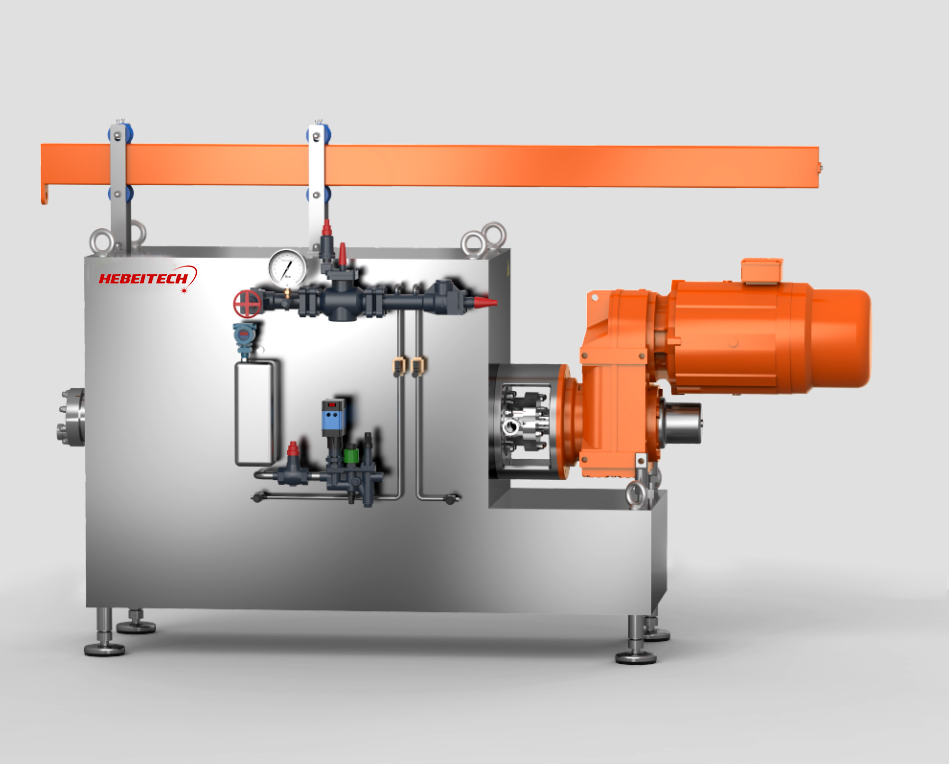

1.SPX-Plus Series Margarine Machine(Ama-Scraper Heat Exchangers)

Ukucindezela okuphezulu, amandla anamandla, umthamo omkhulu wokukhiqiza

Idizayini evamile yokucindezela okungu-120bar, amandla emoto aphezulu angu-55kW, umthamo wokwenza imajarini ungafika ku-8000KG/h

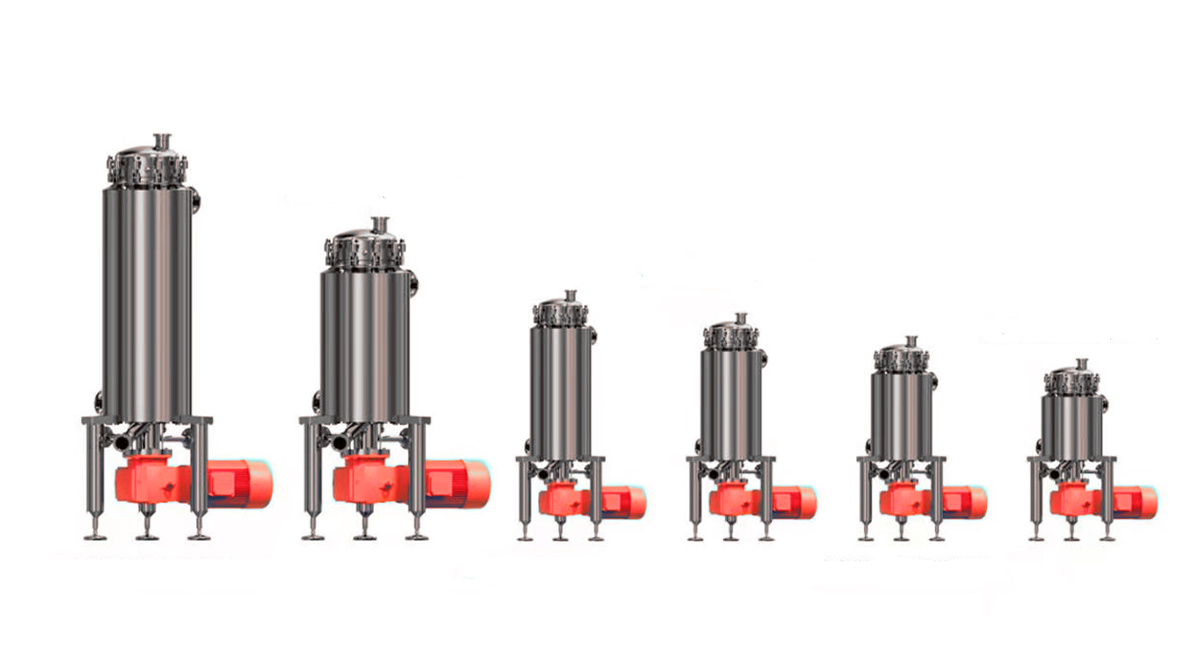

2.SPX Series Scraped Surface Heat Exchanger

Izinga eliphakeme lokuhlanzeka, ukucushwa okucebile, kungenziwa ngokwezifiso

Ireferensi yezidingo zamazinga we-3A, indawo ehlukahlukene yeBlade/Tube/Shaft/Heat ingakhethwa, futhi amamodeli anosayizi abahlukahlukene angakhethwa ukusekela izidingo zokwenza ngokwezifiso.

3.SPA Series Shortening Production Machine (Ama-SSHE)

Isivinini se-shaft esiphakeme, Igebe lesiteshi Lincane, I-scraper yensimbi ende

Ijubane lokuzungezisa ishaft lifinyelela ku-660r/min, igebe lesiteshi liyancipha libe ngu-7mm, i-metal scraper ubude ukuya ku-763mm

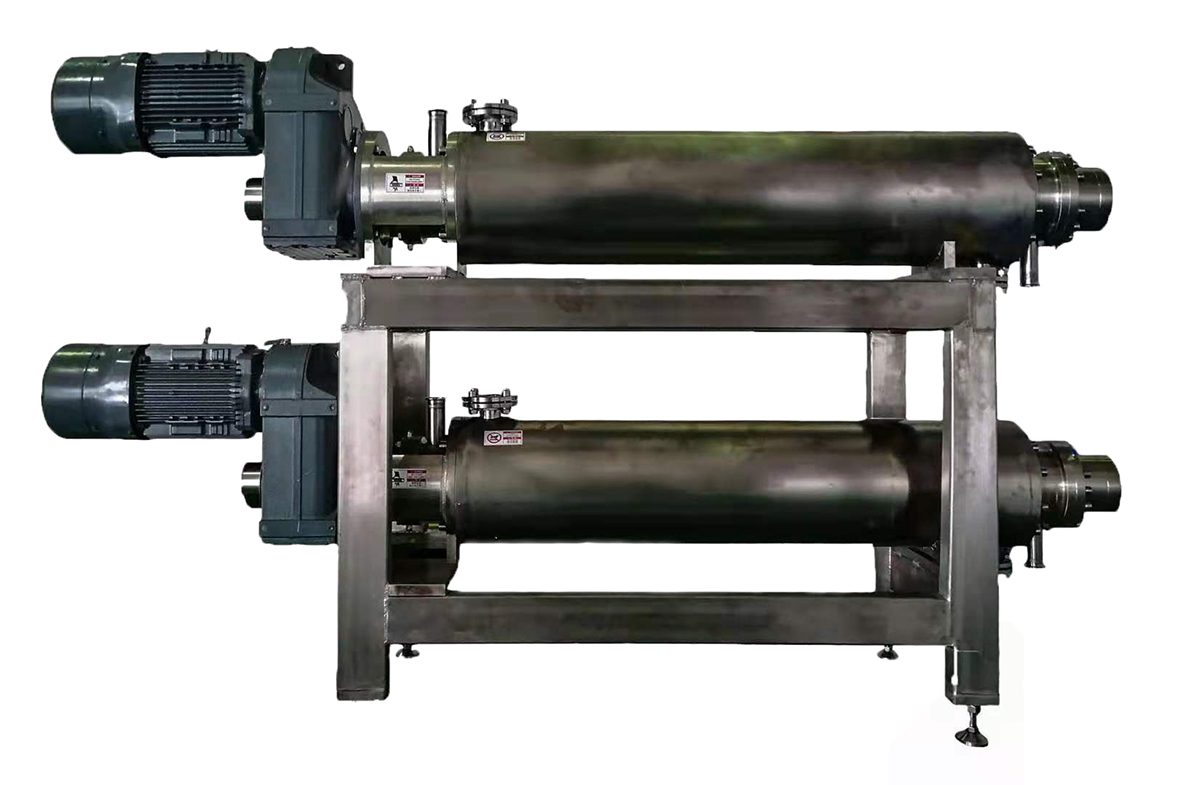

I-4.SPT Series Double Surface Scraper Heat Exchanger

Isivinini se-shaft ephansi, Igebe lesiteshi elibanzi, Indawo enkulu yokushintshanisa ukushisa

Isivinini sokujikeleza kwe-shaft siphansi siye ku-100r/min, igebe lesiteshi liba banzi lifinyelele ku-50mm, ukudluliswa kokushisa okuphindwe kabili, indawo yokudlulisa ukushisa ifike ku-7 square metres.

Imajarini & Ulayini Wokukhiqiza Obufushane

Imajarini kanye nokufinyeza kudume kakhulu embonini yokubhaka, izinto ezingavuthiwe zihlanganisa amafutha esundu, amafutha emifino, amafutha ezilwane, amafutha e-hydrogenated kancane namafutha, uwoyela wasolwandle, uwoyela wesundu, isinqumelo, inyama yenkomo, i-palm stearin, uwoyela kakhukhunathi, njll. Inqubo yokukhiqiza imajarini eyinhloko ithi Measuring——Ingredients Configuration——Filtration——Emulsification——Margarine isiqandisi——I-Pin Rotor Kneading—— (Ukuphumula)———Ukugcwalisa & Ukupakisha. Izinto ezisetshenziswayo ezakha isikhungo sokukhiqiza iMargarine Shortening zihlanganisa amaVotators, Scraped Surface Heat Exchanger, Kneader, Pin Rotor, imajarini yokuphumula ishubhu, umshini wokugcwalisa nokupakisha omfishane, i-homogenizer, ithangi lokufaka i-emulsifying, ithangi lokubhaka, iphampu yomfutho ophezulu, isibulala-magciwane, i-compressor yesiqandisi. , iyunithi yesiqandisi, umbhoshongo wokupholisa, njll.

Lapho, amayunithi e-SPA + SPB + SPC noma amayunithi e-SPX-Plus + SPB + SPCH akha imajarini/umugqa wokufinyeza wekristalu, ongakhiqiza imajarini yetafula, ukufinyeza, imajarini ye-puff pastry neminye imikhiqizo yebhotela. Isakhiwo se-SPA SeriesSSHEUmshini wokwenza omfishane uhlukile. Ngemuva kweminyaka eminingi yokwenza kahle, inokuqina okuphezulu kwemishini, ukucoleka nokuqedwa kwemikhiqizo efinyeziwe kuhola eChina.

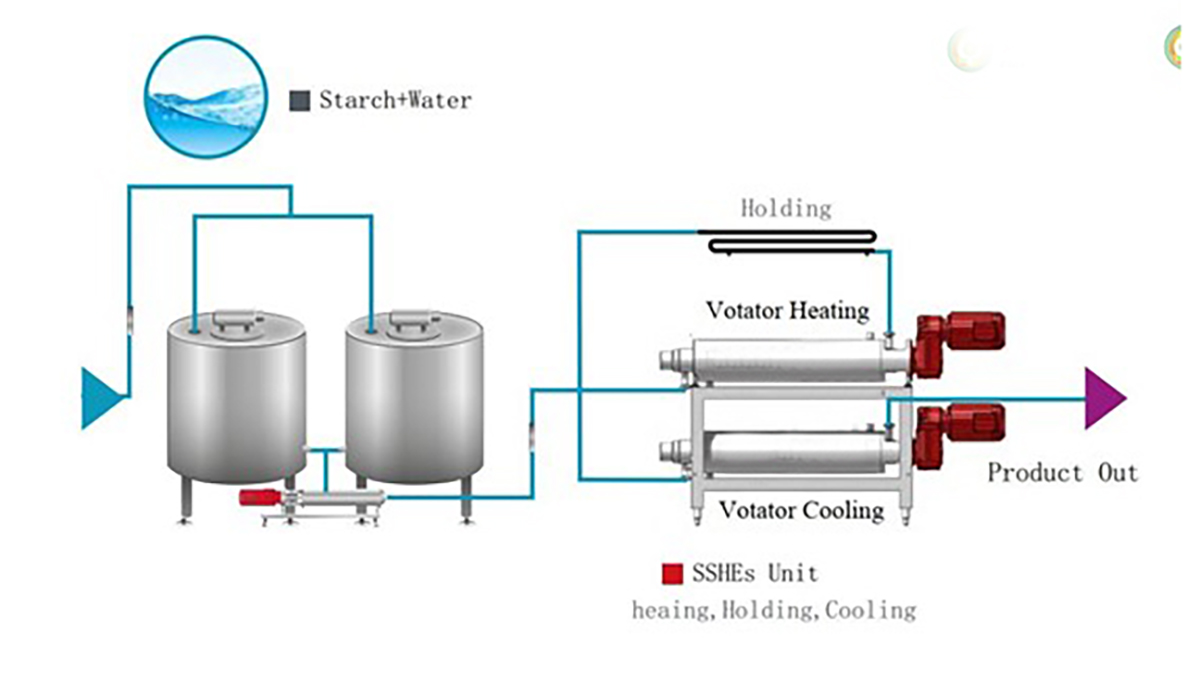

Ngokuvamile, inqubo yokukhiqiza imajarini/ukunciphisa(ighee) yochungechunge lwe-SP iwukuthi:

1. Amafutha kanye nama-Fat blends kanye nesigaba esinamanzi anqunyelwe kusengaphambili emikhunjini emibili ephethe i-emulsion kanye nokuxuba. Ukuhlanganisa o imikhumbi yokubamba/ yokuxuba kwenziwa ngamaseli omthwalo alawulwa uhlelo lokulawula lwe-PLC.

2. Ukucubungula ukuhlanganisa kulawulwa yikhompyutha enengqondo enesikrini sokuthinta. Ithangi ngalinye lokuxuba/lokukhiqiza lifakwe i-high shear mixer ukuze ifake izigaba zikawoyela nezamanzi.

3. I-mixer ifakwe isivinini esishintshashintshayo ukuze kwehliswe isivinini sokuyaluza okuthambile ngemva kokwenziwa kwe-emulsification. Amathangi amabili azosetshenziswa njengethangi lokukhiqiza kanye nethangi le-emulsification ngenye indlela.

4. Ithangi lokukhiqiza nalo lizosebenza njenganoma yimuphi umkhiqizo ogaywe kabusha usuka emugqeni wokukhiqiza. Ithangi lokukhiqiza kuzoba ithangi lamanzi/lekhemikhali lokuhlanza ulayini nokuthuthwa kwendle.

5. I-emulsion evela ethangini lokukhiqiza izodlula kusihlungi/isihluzi esingamawele ukuze kuqinisekiswe ukuthi akukho okuqinile okuzodlula kumkhiqizo wokugcina (imfuneko ye-GMP).

6. Isihlungi/isihluzi sisebenza ngenye indlela ukuhlanza isihlungi. I-emulsion ehlungiwe isuke idlule ku-pasteurizer (imfuneko ye-GMP) equkethe izingxenye ezintathu zama-heaters amabili amapuleti kanye nepayipi elilodwa lokugcina.

7. I-heater yepuleti yokuqala izoshisa i-emulsion yamafutha kuze kufike ekushiseni kwe-pasteurization ngaphambi kokudlula epayipini lokugcinwa ukuze inikeze isikhathi esidingekayo sokubamba.

8. Noma ikuphi ukushisa kwe-emulsion okungaphansi kwezinga lokushisa le-pasteurization elidingekayo kuzogaywa kabusha kubuyiselwe ethangini lokukhiqiza.

9 I-emulsion yamafutha e-pasteurized izongena emshinini wokushisisa wepuleti lokupholisa ukuze iphole ifike cishe ku-5 ~ 7-degree C ngaphezu kwendawo yokuncibilika kawoyela ukuze kuncishiswe amandla okubanda.

10. I-heater yepuleti ishiswa uhlelo lwamanzi ashisayo ngokulawula izinga lokushisa. Ukupholisa amapuleti kwenziwa ngokupholisa amanzi ombhoshongo ngevalvu yokulawula izinga lokushisa okuzenzakalelayo namalophu e-PID.

11. I-emulsion pumping/transfer, kuze kube manje, yenziwa ipompo eyodwa yokucindezela okukhulu. I-emulsion ifakwa kuyunithi yeVotator kanye ne-pin rotor ngezindlela ezihlukene, bese ehlisa izinga lokushisa liye ezingeni lokushisa elifunekayo lokuphuma ukuze kukhiqizwe imajarini/imikhiqizo yokufinyeza edingekayo.

12. I-semi-solid oil ephuma emshinini wokuvota izobe ipakisha noma igcwaliswe ngomshini wokugcwalisa imajarini nomshini wokupakisha.

Umshini Wokuvotela we-SP Series/I-Sauce Votator

Ukudla okuningi okulungiselelwe noma eminye imikhiqizo akuzuzi ukudluliswa kokushisa okuphezulu ngenxa yokungaguquguquki kwayo. Isibonelo, imikhiqizo yesitashi, i-scaue, inqwaba, enamathelayo, enamathelayo noma ecwebezelayo equkethwe emikhiqizweni yokudla ingavala ngokushesha noma ingcolise izingxenye ezithile zesishintshi sokushisa. I-advantage scrap surface heat exchanger ihlanganisa imiklamo ekhethekile eyenza kube isishintshi sokushisa esiyimodeli sokushisisa noma ukupholisa le mikhiqizo elimaza ukudluliswa kokushisa. Njengoba umkhiqizo uphonswa emgqonyeni wempahla ye-votator heat exchanger, iyunithi ye-rotor kanye ne-scraper iqinisekisa ukusatshalaliswa kwezinga lokushisa elilinganayo, ikhuhla impahla kude nendawo yokushintsha ukushisa ngenkathi ixuba ngokuqhubekayo nangokumnene umkhiqizo.

Isistimu yokupheka isitashi yochungechunge lwe-SP iqukethe isigaba sokushisa, isigaba sokugcina ukushisa kanye nesigaba sokupholisa. Kuye ngokukhiphayo, lungiselela isishintshi sokushisa esilahliwe esisodwa noma eziningi. Ngemva kokuba i-starch slurry ihlanganiswe ethangini lokuhlanganisa, iphonswa ohlelweni lokupheka ngepompo yokuphakela. Isishintshi sokushisa samavoti esiwuchungechunge lwe-SP sasebenzisa isitimu njengesisetshenziswa sokushisisa ukushisisa udaka lwesitashi ukusuka ku-25°C kuya ku-85°C, lapho-ke, udaka lwesitashi lwagcinwa endaweni yokubamba imizuzu emi-2. Izinto ezisetshenziswayo zapholiswa zisuka ku-85°C zaya ku-65°CAma-SSHEnjengethuluzi lokupholisa nokusebenzisa i-ethylene glycol njengendawo yokupholisa. Impahla epholile iya esigabeni esilandelayo. Lonke uhlelo lungahlanzwa yi-CIP noma i-SIP ukuze kuqinisekiswe inkomba yenhlanzeko yalo lonke uhlelo.

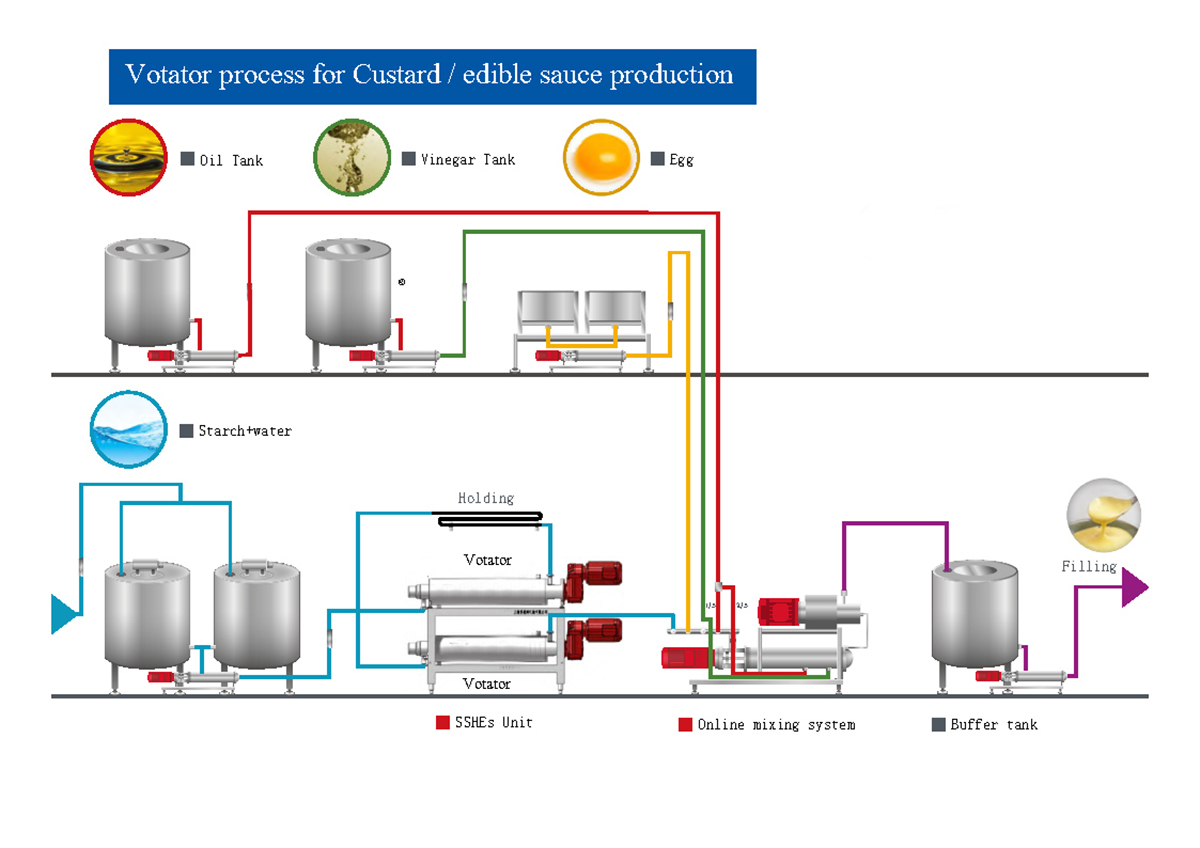

I-SP Series Custard/Mayonnaise Production Line

I-Custard / imayonnaise / ulayini wokukhiqiza isoso odliwayo uwuhlelo olusebenzayo lwemayonnaise kanye nezinye izithako zesigaba samafutha / samanzi emulsified, ngokuya ngenqubo yokukhiqiza imayonnaise nokunye okunjalo, okunyakazisayo. imishini yethu ifaneleka kakhulu ekuxubeni imikhiqizo e-viscosity yayo efana nemayonnaise. I-Emulsification iwumgogodla wokukhiqizwa kwemayonnaise kanye nochungechunge lweVotatorAma-SSHE, samukela indlela yokukhiqiza esekelwe kumgomo we-on-line wesigaba sesithathu se-micro emulsification, isigaba samafutha / samanzi sihlukaniswa ngamayunithi amancane, bese sihlangana endaweni yokusebenza ye-emulsifying, siqedele ukuhlanganiswa phakathi kwe-emulsifier kanye ne-emulsion yamafutha / amanzi. . Lo mklamo uvumela umklami ukuthi acacise ukuhlukaniswa kwendawo yokusebenza kuyo yonke isistimu yesishintshi sokushisa esakhiwe, futhi kangcono ukulungisa nokuthuthukisa yonke inqubo yokukhiqiza. Njengasezindaweni zokusebenza ze-emulsion, uchungechunge lwe-Votator luqinisa amandla e-emulsifying, lwenza isigaba sikawoyela sifakwe emulsified kumaconsi e-microscopic liquid futhi ahlanganiswe nesigaba samanzi kanye ne-emulsifier okokuqala ukuze uthole uhlelo lwe-emulsion oluzinzile lwamafutha emanzini, ngaleyo ndlela. ukuxazulula izinkinga ezinjengokusabalalisa usayizi wamaconsi kawoyela obanzi kakhulu, ukuzinza okungekuhle kohlobo lomkhiqizo, nokuba sengozini engcupheni yokuchitheka kukawoyela njll., okubangwa kalula indlela ye-macro emulsification kanye nezindlela zokuxuba ezinyakazayo eziphazamisana.

Ngaphezu kwalokho, izishintshi zokushisa ezikhuhlayo ze-SP zibuye zisetshenziswe kwenye Ukushisisa, Ukupholisa, i-Crystallization, i-Pasteurization, inzalo, i-Gelatinize ne-Evaporation inqubo eqhubekayo.

Insiza Eyengeziwe

A) Imibhalo yokuqala:

I-Scraped Surface Heat Exchangers, Ukubuyekezwa Okubalulekile Kwesayensi Yokudla Nokudla Okunomsoco,Umqulu 46, Ukukhishwa Kwesi-3

U-Chetan S. Rao noRichard W. Hartel

Landa izingcaphunohttps://www.tandfonline.com/doi/abs/10.1080/10408390500315561

B) Imibhalo yokuqala:

Ama-Margarines, i-ULLMANN'S Encyclopedia of Industrial Chemistry, i-Wiley Online Library.

U-Ian P. Freeman, u-Sergey M. Melnikov

Landa izingcaphuno:https://onlinelibrary.wiley.com/doi/abs/10.1002/14356007.a16_145.pub2

C) Uchungechunge lwe-SPX Imikhiqizo yokuncintisana efanayo:

I-SPX Votator® II I-Scraped Surface Heat Exchangers

Vakashela Isixhumanisi:https://www.spxflow.com/products/brand?types=heat-exchanger&brand=waukesha-cherry-burrell

D) Uchungechunge lwe-SPA kanye nochungechunge lwe-SPX Imikhiqizo yokuncintisana efanayo:

I-Scraped Surface Heat Exchangers

Vakashela Isixhumanisi:https://www.alfalaval.com/products/heat-transfer/scraped-surface-heat-exchangers/scraped-surface-heat-exchangers/

E) Uchungechunge lwe-SPT Imikhiqizo efanayo yokuncintisana:

I-Terlotherm® Iziguquli Zokushisa Zokushisa Eziklitshiwe

Vakashela Isixhumanisi:https://www.proxes.com/en/products/machine-families/heat-exchangers#data351

F) Uchungechunge lwe-SPX-Plus Imikhiqizo yokuncintisana efanayo:

I-Perfector® Scraped Surface Heat Exchangers

Vakashela Isixhumanisi:https://gerstenbergs.com/polaron-scraped-surface-heat-exchanger

G) Uchungechunge lwe-SPX-Plus Imikhiqizo efanayo yokuncintisana:

I-Ronothor® Iziguquli Zokushisa Zokushisa Eziklitshiwe

Vakashela Isixhumanisi:https://ro-no.com/en/products/ronothor/

H) Uchungechunge lwe-SPX-Plus Imikhiqizo yokuncintisana efanayo:

I-Chemetator® Iziguquli Zokushisa Zokushisa Eziklitshiwe

Vakashela Isixhumanisi:https://www.tmcigroup.com/wp-content/uploads/2017/08/Chemetator-EN.pdf