Pin Rotor Machine Izinzuzo-SPCH

Kulula Ukulondoloza

Idizayini iyonke ye-SPCH pin rotor isiza ukushintshwa kalula kwezingxenye zokugqoka ngesikhathi sokulungiswa nokugcinwa. Izingxenye ezishelelayo zenziwe ngezinto eziqinisekisa ukuqina okude kakhulu.

Izinto zokwakha

Izingxenye zokuxhumana zomkhiqizo zenziwe ngensimbi engagqwali yekhwalithi ephezulu. Izimpawu zomkhiqizo ziyizigxivizo zemishini ezilinganiselwe kanye nezindandatho ze-O-grade. Indawo yokubeka uphawu yenziwe nge-silicon carbide ehlanzekile, futhi izingxenye ezinyakazayo zenziwe nge-chromium carbide.

Ukuvumelana nezimo

Umshini we-SPCH pin rotor uyisisombululo esihle kakhulu sokukhiqiza sokuqinisekisa i-crystallization efanele kanye nokuvumelana kwezinhlobonhlobo zemajarini kanye nemikhiqizo efinyeziwe. Umshini wethu we-SPCH pin rotor unikeza ukuguquguquka kwenqubo yokukhiqiza ngendlela ebaluleke kakhulu. Ukulungiswa kungenziwa ukuze kushintshwe izinga lokuqina kanye nobude bokuxova. Lokhu kukuvumela ukuthi ushintshe uhlobo lwamafutha, kuye ngokutholakala kanye nesidingo emakethe. Ngalokhu kuvumelana nezimo, ungasebenzisa ithuba elihle lokuguquguquka kwentengo kawoyela ngaphandle kokufaka engozini ikhwalithi yomkhiqizo.

Isimiso Sokusebenza

I-SPCH pin rotor yamukela ukwakheka kwephinikhodi eyicylindrical ukuze kuqinisekiswe ukuthi impahla inesikhathi esanele sokushukumisa ukuphula isakhiwo senethiwekhi yekristalu yamafutha aqinile futhi icwenge izinhlamvu zekristalu. Injini iyinjini elawula isivinini esishintshashintshayo. Isivinini sokuxuba singalungiswa ngokuya ngokuqukethwe kwamafutha aqinile ahlukene, okungahlangabezana nezidingo zokukhiqiza ukwakheka okuhlukahlukene kwabakhiqizi bemajarini ngokuya ngezimo zemakethe noma amaqembu abathengi.

Lapho umkhiqizo oqediwe we-grease oqukethe i-crystal nuclei ungena ku-kneader, i-crystal izokhula ngemva kwesikhathi esithile. Ngaphambi kokwenza isakhiwo senethiwekhi jikelele, yenza ukugqugquzela nokuxova ngomshini ukuze uphule isakhiwo senethiwekhi esakhiwe ekuqaleni, usenze siphinde sikhanye, sinciphise ukuhambisana futhi sikhulise ipulasitiki.

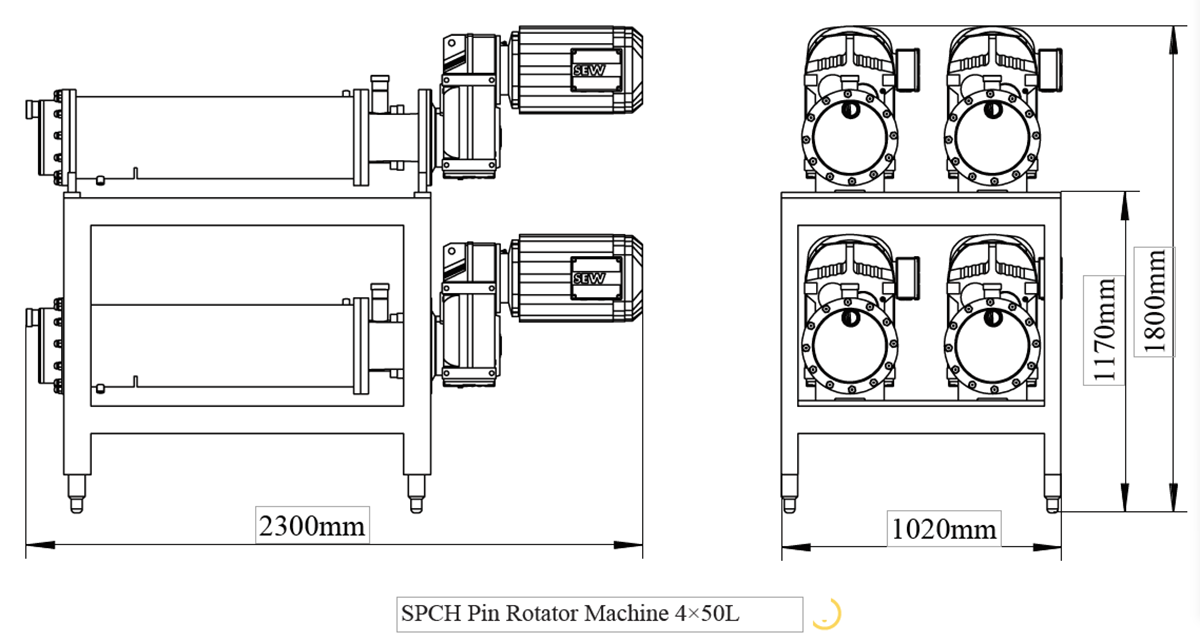

Umshini we-Pin Rotor-SPCH

| Imingcele yezobuchwepheshe | I-Technical Spec. | Iyunithi | 30L | 50L | 80L |

| Umthamo olinganiselwe | Ivolumu Yezibizo | L | 30 | 50 | 80 |

| Amandla emoto amakhulu | Amandla Ayinhloko | kw | 7.5 | 7.5 | 9.2 noma 11 |

| I-diameter ye-spindle | Dia. Of Main Shaft | mm | 72 | 72 | 72 |

| Ukususwa kwe-bar eshukumisayo | Phina Isikhala Sesikhala | mm | 6 | 6 | 6 |

| Ibha yokuxuba iyimvume ngodonga lwangaphakathi lomgqomo | I-Pin-Inner Wall Space | m2 | 5 | 5 | 5 |

| Ububanzi/ubude bomzimba wesilinda | I-Inner Dia./Ubude Beshubhu Elipholisayo | mm | 253/660 | 253/1120 | 260/1780 |

| Inani lemigqa yenduku yokunyakazisa | Imigqa Yephini | pc | 3 | 3 | 3 |

| Ijubane lokuphotha lenduku enyakazayo | Isivinini se-Norminal Pin Rotor | rpm | 50-340 | 50-340 | 50-340 |

| Ingcindezi yokusebenza ephezulu (uhlangothi lomkhiqizo) | I-Max.Working Pressure (uhlangothi lwezinto) | ibha | 60 | 60 | 60 |

| Ingcindezi yokusebenza ephezulu (uhlangothi lwamanzi okugcina ukushisa) | I-Max.Working Pressure (uhlangothi lwamanzi ashisayo) | ibha | 5 | 5 | 5 |

| Ubukhulu bokusebenza kwepayipi lomkhiqizo | Icubungula usayizi wepayipi | I-DN50 | I-DN50 | I-DN50 | |

| Izilinganiso ze-interface zamapayipi amanzi avaliwe | Usayizi Wepayipi Lokuhlinzeka Amanzi | DN25 | DN25 | DN25 | |

| Usayizi womshini | I-Dimension Ephelele | mm | 1840*580*1325 | 2300*580*1325 | 2960*580*1325 |

| Isisindo | Isisindo esikhulu | kg | 450 | 600 | 750 |